Product Description

Surface Tissue is an excellent surface material for FRP products. It is made from the Wet Chopped Strand glass fibers in paper-making process.

Product Benefits

•Rapid wet out

•Smooth surface appearance of finished products

•Good waterproof performance

•Good mechanical properties

Technical Characteristics

|

Sizing Type

|

Area Weight (g/m2)

|

Width (mm)

|

Longitudinal Tensile Strength (N/50mm)

|

Wet-out Rate(s)

|

Loss on Ignition (%)

|

Moisture Content (%)

|

|

/

|

ISO 3374

|

ISO 5025

|

ISO 3342

|

EN 14118

|

ISO 1887

|

ISO 3344

|

|

Silane

|

±10%

|

≤200

|

±2

|

≥25

|

<15(Two layers)

|

7±2

|

≤0.30

|

|

>200

|

±5

|

|

Glass type

|

Area Weight(g/m2)

|

Thickness (mm)

|

Width(mm)

|

Length(m)

|

|

ECR

|

30

|

0.15

|

1000

|

850

|

Note:

1.E/ECR/ECT glass types are available.

2.Low/Medium/High LOI are available.

|

Package

|

Roll Weight (kg/roll)

|

Core Inside/Outside Diameter(mm)

|

Number of roller per pallet

|

Pallet size(mm) L*W*H

|

|

ST(ECR)30M-1000

|

25.5

|

76.5/530

|

4

|

1140*1140*110

|

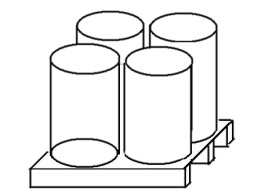

Pallets illustration

Note: Products can be packed according to the customer's request.

Storage

The products should be stored away from heat and moisture, and in their original packaging. The best conditions are: temperatures between 15 and 35 ºC; humidity between 35 and 65 %.

If the product is not stored under these specifications, it is advisable to condition it in the workshop for at least 24 hours before use to prevent condensation.

CPIC recommends that the material be used according to FIFO (first in, first out) method. It is recommended the use of a spacer plate (10mm) between the pallets.