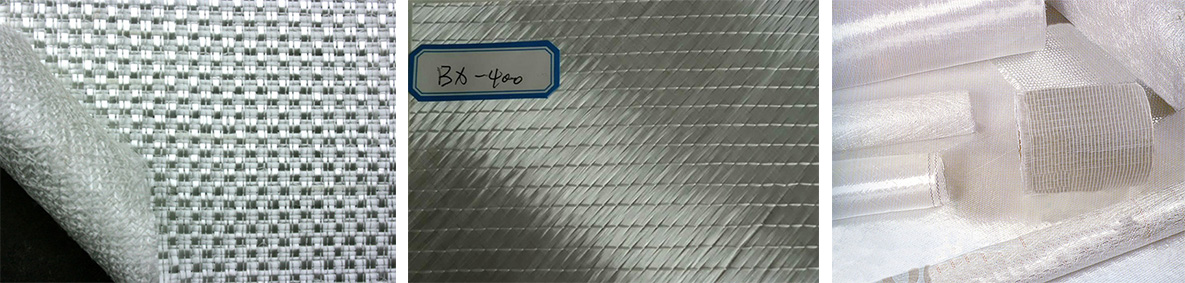

Multi axial fabric reinforcements are produced on large looms where fibers are directionally oriented (X and Y axis, or sometimes referred to as the 0°, 90° and 45° orientation) in multiple layers and then stitched together to keep the fibers in place. The resulting fabric is trimmed and rolled. This production process allows for a multitude of fiber orientation patterns, thickness, weight distribution and the incorporation of different types of reinforcements like carbon fiber or aramid fiber. Fabrics can be balanced, with the same amount of fiber used in both the X and Y axis or unbalanced with addition fiber in one axis to provide more reinforcement strength in that direction. Using knitted fabrics allows for significant part or laminate design flexibility and is widely used in boat building, transportation, wind blades and recreational products where specific strength orientation in the laminate is optimal.

E-glass fiber mULTI-AXIAL FABRIC

|

Product Series |

Product No. |

Overall Density(g/m2) |

Layer Density(g/m2) |

Mass Per Unit Area(%) |

Moisture Content(%) |

|||||

|

|

|

|

0° |

90° |

+45° |

-45° |

Chop |

Yarn |

ISO3374-2000 |

ISO3344-1997 |

|

Unidirectional |

E-T140 |

141.08 |

|

135.83 |

|

|

|

5.25 |

±5 |

≤0.20 |

|

E-T160 |

160.45 |

|

155.86 |

|

|

|

4.59 |

±5 |

≤0.20 |

|

|

E-T210 |

213.46 |

|

208.61 |

|

|

|

4.85 |

±5 |

≤0.20 |

|

|

E-T280 |

279.25 |

|

274 |

|

|

|

5.25 |

±5 |

≤0.20 |

|

|

E-T300 |

291.69 |

|

286.44 |

|

|

|

5.25 |

±5 |

≤0.20 |

|

|

E-T310 |

309.23 |

|

303.98 |

|

|

|

5.25 |

±5 |

≤0.20 |

|

|

E-T400 |

405.2 |

|

399.95 |

|

|

|

5.25 |

±5 |

≤0.20 |

|

|

E-T450 |

450.36 |

|

445.11 |

|

|

|

5.25 |

±5 |

≤0.20 |

|

|

E-T520 |

518.65 |

|

512.4 |

|

|

|

6.25 |

±5 |

≤0.20 |

|

|

E-T550 |

547.86 |

|

542.61 |

|

|

|

5.25 |

±5 |

≤0.20 |

|

|

E-T600 |

603.04 |

|

597.79 |

|

|

|

5.25 |

±5 |

≤0.20 |

|

|

E-T900 |

905.72 |

|

900.47 |

|

|

|

5.25 |

±5 |

≤0.20 |

|

|

Biaxial |

E-BX300 |

306.01 |

|

|

150.33 |

150.33 |

|

5.35 |

±5 |

≤0.20 |

|

E-BX450 |

456.33 |

|

|

225.49 |

225.49 |

|

5.35 |

±5 |

≤0.20 |

|

|

E-BX500 |

606.67 |

|

|

300.66 |

300.66 |

|

5.35 |

±5 |

≤0.20 |

|

|

E-BX800 |

807.11 |

|

|

400.88 |

400.88 |

|

5.35 |

±5 |

≤0.20 |

|

|

E-BX1200 |

1207.95 |

|

|

601.3 |

601.3 |

|

5.35 |

±5 |

≤0.20 |

|

|

E-BXM450/225 |

681.33 |

|

|

225.49 |

225.49 |

225 |

5.35 |

±5 |

≤0.20 |

|

|

E-BXM600/225 |

830.75 |

|

|

300.2 |

300.2 |

225 |

5.35 |

±5 |

≤0.20 |

|

|

E-BXM600/300 |

905.75 |

|

|

300.2 |

300.2 |

300 |

5.35 |

±5 |

≤0.20 |

|

|

Longitudinal Triaxial |

E-TLX600 |

614.9 |

3.6 |

|

300.65 |

300.65 |

|

10 |

±5 |

≤0.20 |

|

E-TLX750 |

742.67 |

236.22 |

|

250.55 |

250.55 |

|

5.35 |

±5 |

≤0.20 |

|

|

E-TLX1180 |

1172.42 |

661.42 |

|

250.5 |

250.5 |

|

10 |

±5 |

≤0.20 |

|

|

E-TLX1850 |

1856.86 |

944.88 |

|

450.99 |

450.99 |

|

10 |

±5 |

≤0.20 |

|

|

E-TLXM1260/100 |

1367.03 |

| ||||||||