Product Description

It is used in pultrusion applications in polyester resin systems or vinyl resin systems. The direct rovings can be used to manufacture the optical cable reinforced core, pultruded profiles.

Product Benefits

◎ Compatibility with multiple of resin systems

◎ Complete and fast wet-out

◎ Good mechanical properties

Technical Characteristics

|

Sizing type

|

Roving density [tex(g/km)]

|

Filament Diameter

(%)

|

Moisture content

(%)

|

LOI(%)

|

Tensile strength(N/Tex)

|

|

——

|

ISO1889

|

ISO1888

|

ISO3344

|

ISO1887

|

ISO3341

|

|

Silane

|

nominal value±5%

|

nominal value±1

|

≤0.10

|

nominal value±0.1

|

<1200tex

|

≥0.35N/Tex

|

|

≥1200tex

|

≥0.30N/Tex

|

|

Linear Density

|

Glass type

|

Filament Diameter[μm]

|

linear density [tex(g/km)]

|

LOI(%)

|

|

600 TEX

|

E/ECR/TM

|

14

|

600

|

0.40

|

|

1200 TEX

|

16

|

1200

|

0.45

|

|

2400 TEX

|

22

|

2400

|

0.45

|

|

4800 TEX

|

24

|

4800

|

0.45

|

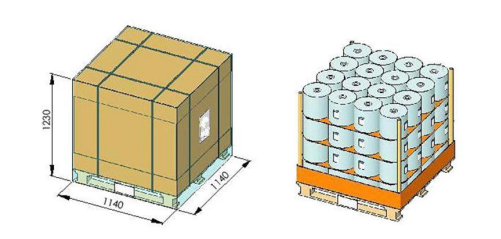

Packaging

Each roll of roving is wrapped by shrinkage packing or tacky-pack, then put into pallet or carton box, 48 rolls or 64 rolls each pallet.

Pallets characteristics

|

Product

|

Levels per Pallet

|

Rovings per Pallet

|

Rovings per Level

|

Pallet Dimensions L x W x H (mm)

|

Net Weight approx. (Kg)

|

|

Direct Roving

|

3

|

48

|

16

|

1140 x 1140 x 940

|

816

|

|

Direct Roving

|

4

|

64

|

16

|

1140 x 1140 x 1230

|

1088

|

Note:Please contact us if you have special requirements.

Storage

Unless otherwise specified, the fiberglass products should be stored in a dry, cool and moisture-proof area. The room temperature and humidity should be always maintained at 15℃~35℃ and 35% ~ 65%.It is best if the product is used within 12 months after production date.The fiberglass products should remain in their original packaging until just prior to user .

To ensure safety and avoid damage to the product, the pallets should not be stacked more than three layers high. When the pallets are stacked in 2 or 3 layers, special care should be taken to correctly and smoothly move the top pallet.