Description

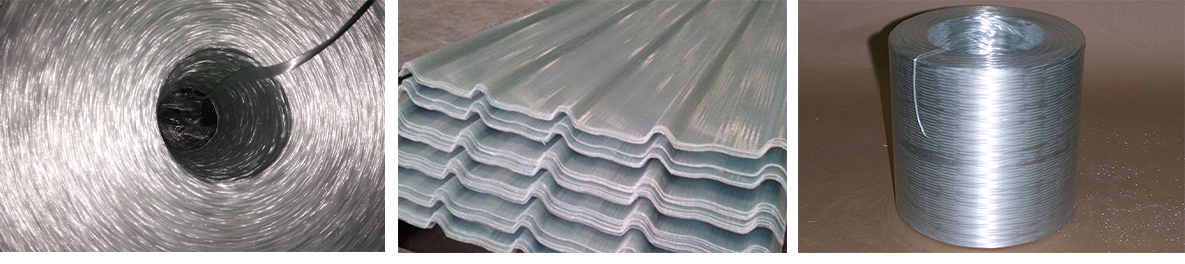

Assembled Panel Roving for continuous panel molding process is coated with a silane-based sizing compatible with unsaturated polyester.

It delivers light weight, high strength and high impact strength,and is designed to manufacture transparent panels.

Linear Density

2400tex,4800tex

Product Features

◎ Good dispersion after chopping

◎ Excellent anti-static property

◎ Good wet-out

◎ Good refractive index matching between resin and glass fiber

◎ Excellent mechanical property of composite parts

Package

The roving to be packed on pallet.Each pallet is supported by very strong papercoil at the four corners of pallet, then packed in a polythene stretched film.

Storage

Unless otherwise specified, the fiberglass products should be stored in a dry, cool and moisture-proof area. The room temperature and humidity should be always maintained at 15℃~35℃ and 35% ~ 65%.It is best if the product is used within 12 months after production date.The fiberglass products should remain in their original packaging until just prior to user .

To ensure safety and avoid damage to the product, the pallets should not be stacked more than three layers high. When the pallets are stacked in 2 or 3 layers, special care should be taken to correctly and smoothly move the top pallet.

Technical DATE SHEET

|

PRODUCT NAME

|

E-GLASS FIBER PANEL ROVING

|

|

TEST ITEM

|

STANDARD NO.

|

STANDARD VALUE

|

|

LINEAR DENSITY(%)

|

ISO 1889-1997

|

±6

|

|

STIFFNESS(MM)

|

ISO 3375-1987

|

90-130

|

|

COMBUSTIBLE MATTER CONTENT(%)

|

iso 1887-1995

|

0.7±0.15

|

|

moisture content(%)

|

iso 3344-1997

|

≤0.10

|

|

SPLITTING RATIO(%)

|

Q/JS 4303

|

≥85

|